- TNAS – Pool Dehumidifacition Unit

- TIGK-HP – Heat Pump Heat Recovery UNIT

- TIGK – Heat Recovery Unit

- TDEF Axial Jet Fan

- TDEF – Axial Fume Ezhoust Fons

- TKAF – Axial Fresh Air Fans

- TBF – Radial Roof Fan

- TDBF – Roof Fan With Vertical Throw

- TDKF – Rectangle Air Duct Fan

- TCF – Vertical Outlet Roof Fan

- TDCF – Vertical Outlet Roof Fan

- TAKF – Acoustic Insulated Duct Fan

- TSF – Duct Type Fresh Air Fan For Shelter

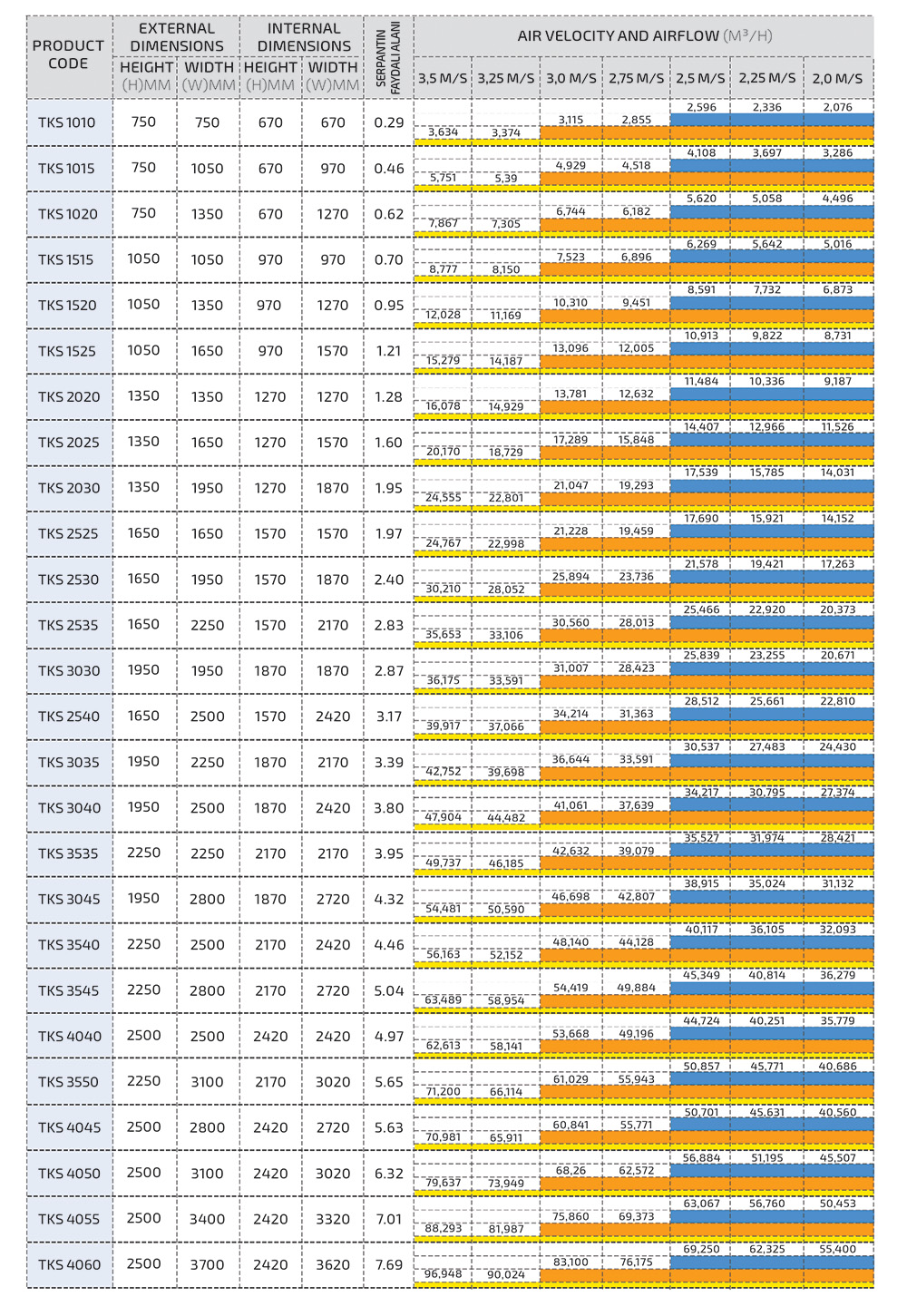

- TKS – Air Handling Unit

- THF – Cell Fan

- THMF-E – Kitchen Egzost Fan With Electrostatic Filter

- TKMF – Duct Type Kitchen Fan

- TRT – PACKAGE UNIT (Roof Top)

- TKS-H HYGIENIC AIR HANDLING UNIT

The air handling units, which are designed as modular, are produced in the range of 1.000 m3/h – 125.000 m3/h, by using the panels at 40 mm thickness with stone wool isolation in the double walled construction. The TEZEL Air Conditioning Units are used for air conditioning in the residences, work places and industrial facilities. The exterior surface of the air conditioning units are galvanized sheet painted with RAL 9002 color; and the interior surfaces can be produced with galvanized, painted or stainless steel upon demand and application. In order to ensure tightness, one of the most significant indicators of the performance of the air conditioning unit, EPDM based gaskets are used. In order to maintain the high productivity of the serpentine and the filters, the stray current during the air flow is prevented with the special designs. The filters are selected suitably for the requirements of both the environment and the process. The dumpers used in the air handling units and cell aspirators are manufactured with the aluminum profile, aluminum wing and plastic based gears. The gears are out of the air flow. The plastic gaskets are used in order to ensure the tightness in the damper wings. Plated, rotor or battery-type heat recovery elements are used for the energy productivity which is of vital importance in this day and age. According to the air volume and total static pressure difference, the ventilators driven with the appropriate power engines are selected as forward curved close-blade or backward curved rare-blade based on the required design criteria. The fans having certified performance tests are used. The engines are at the IP55 segment as a standard and comply with the CE norms.

The air handling units, which are designed as modular, are produced in the range of 1.000 m3/h – 125.000 m3/h, by using the panels at 40 mm thickness with stone wool isolation in the double walled construction. The TEZEL Air Conditioning Units are used for air conditioning in the residences, work places and industrial facilities. The exterior surface of the air conditioning units are galvanized sheet painted with RAL 9002 color; and the interior surfaces can be produced with galvanized, painted or stainless steel upon demand and application. In order to ensure tightness, one of the most significant indicators of the performance of the air conditioning unit, EPDM based gaskets are used. In order to maintain the high productivity of the serpentine and the filters, the stray current during the air flow is prevented with the special designs. The filters are selected suitably for the requirements of both the environment and the process. The dumpers used in the air handling units and cell aspirators are manufactured with the aluminum profile, aluminum wing and plastic based gears. The gears are out of the air flow. The plastic gaskets are used in order to ensure the tightness in the damper wings. Plated, rotor or battery-type heat recovery elements are used for the energy productivity which is of vital importance in this day and age. According to the air volume and total static pressure difference, the ventilators driven with the appropriate power engines are selected as forward curved close-blade or backward curved rare-blade based on the required design criteria. The fans having certified performance tests are used. The engines are at the IP55 segment as a standard and comply with the CE norms.